2025-11-05

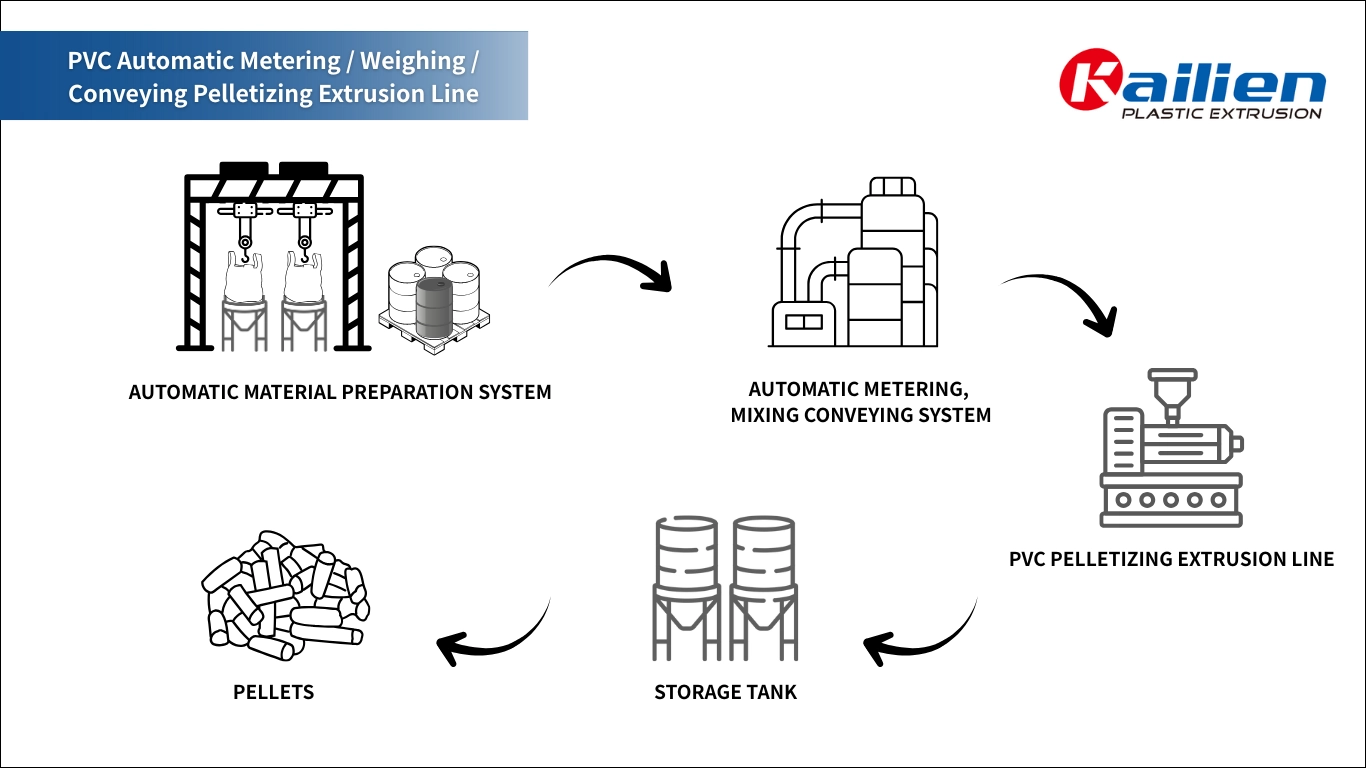

In modern PVC production, automation plays a critical role in improving efficiency and consistency. Kailien's PVC Pelletizing Turnkey System integrates automatic conveying and precise weighing technologies, enabling manufacturers to achieve stable production, consistent product quality, and optimized energy usage.

Automatic Conveying System

1. Automatic Conveying System

The automatic conveying system replaces manual material handling by using sealed pipelines and vacuum loaders to transport PVC powder, CaCO₃, and additives from storage silos directly to the mixer or feeder. This system not only reduces labor costs and contamination risks but also ensures a clean and continuous material flow throughout the production line.

2. Automatic Weighing System

Kailien's automatic weighing and dosing system is designed for PVC powder, CaCO₃ powder, and multiple oil components. With high-precision electronic scales and PLC control, it automatically calculates and dispenses each material according to preset formulas, ensuring accurate proportions for every batch. This precise dosing system greatly enhances product consistency and minimizes human error.

3. Complete Pelletizing Line Integration

After mixing and weighing, materials are fed into Kailien’s PVC Twin Screw Pelletizing Extruder, ensuring uniform melting, mixing, and pelletizing. The entire line, from material feeding, conveying, weighing, mixing to pelletizing, is fully automated and digitally monitored.

( PVC Automatic Metering / Weighing / Conveying Pelletizing Extrusion Line)

Why Manufacturers Choose Automation?

👉🏼 Many PVC manufacturers face similar production challenges:

By integrating automatic conveying + precise weighing, manufacturers gain:

- Unstable product quality due to manual dosing variations

- High labor dependency and increasing manpower costs

- Powder leakage, dust issues, and low plant cleanliness

- Inconsistent production efficiency and frequent line interruptions

By integrating automatic conveying + precise weighing, manufacturers gain:

- Stable and repeatable quality: every batch follows the formula with zero deviation

- Reduced manpower by 30–50%: less material handling, fewer human errors

- Cleaner and safer workplace: closed-loop conveying prevents dust exposure

- Continuous and uninterrupted production: materials always arrive on time

( Complete set of mixing system)

Automation is not about replacing people, it's about eliminating uncertainties.

A PVC pelletizing line that relies on manual feeding and dosing will always struggle with unstable quality, rising labor costs, and operational risks. This is why more factories are shifting from equipment purchasing to seeking a strategic, long-term system upgrade. Kailien's role is not only to supply machines, but to re-engineer the production flow so manufacturers can run a cleaner, smarter, and more predictable PVC pelletizing operation for years to come.

( Turnkey Pelletizing Extrusion Plant Equipment)

Looking to learn more about designing your PVC pelletizing extrusion line?

Contact Kailien today for technical advice and customized machine solutions.

PVC Pelletizing Extrusion Line | Kailien

- Model: KK-100TP

- Product Type: PVC Pipe/Injection/Foam/Medical Grade/Electric Wires Pellet.

- Using the SCR system, it can save 25% of electricity, precisely control the temperature deviation within ±1 degree, and save electricity.

The Core of Sustainable Manufacturing: Reshaping Engineering Plastic Waste with Recycling Pelletizers (Blog)

Advantages of Utilizing an Automated Conveying System (Blog)

The Advantages and Application of Twin Screw Pelletizing Extrusion Line (Blog)

If you wish to know more about the Pelletizing Extruder, Contact Kailien's experienced sales team!